Wiring Accessories

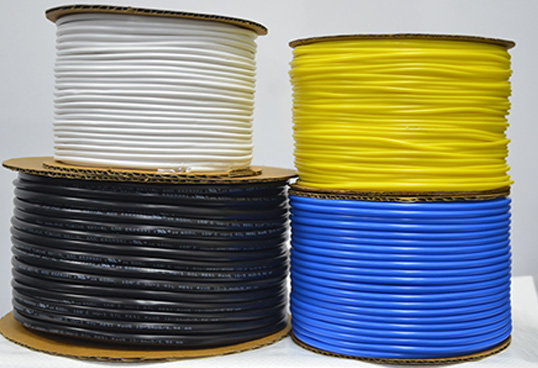

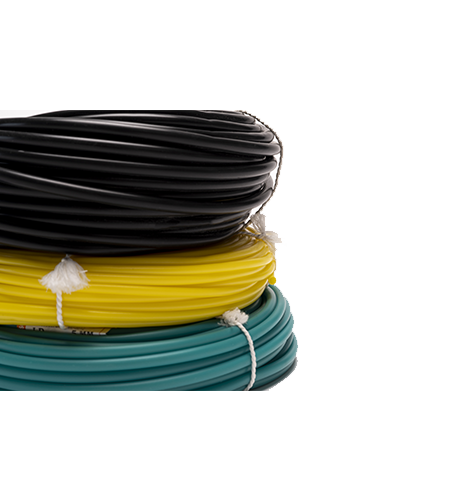

PVC Tubings

UL Approved

SGI’s Non Heat Shrinkable Flexible PVC Tubing are recognized & listed by UL vide file no E529391 (YDPU2/ YDPU8) for both 300 V and 600 V with 900C & 1050C applications for Sizes of Inner Dia from 0.50 mm to 19.0 mm) for all colors except clear.

At a Glance

- Color: Standard Color Black & White, other colors are available on request

- Length: As mentioned in the above chart or as per your requirement.

- Other Sizes: Sizes of any Id’s ranging from ID-0.50mm up to ID-19mm can be supplied against order with MOQ.

- Write to us for more details at info@sgiwiring.com

- N.B: UL 224 PVC Tubing’s also available at 90oC.

- To order the same suffix ‘A’ after the SGI part no.

- Wiring Accessories

- In-Stock

- Coming Soon

SL300 PVC TUBING for 300 V for 105 oC

SL600 PVC TUBING for 600 V for 105 oC

| Product Code | ID (mm) | Avg. Wall Th. | Size | Ft. | Mtr. |

|---|---|---|---|---|---|

| SLUL3-3101 | 0.5 | 0.35 | 24 AWG | 1000 | 304.8 |

| SLUL3-3102 | 1.07 | 0.35 | 18 AWG | 1000 | 304.8 |

| SLUL3-3103 | 1.6 | 0.35 | 14 AWG | 1000 | 304.8 |

| SLUL3-3104 | 2.16 | 0.35 | 12 AWG | 1000 | 304.8 |

| SLUL3-3105 | 2.69 | 0.35 | 10 AWG | 1000 | 304.8 |

| SLUL3-3106 | 3 | 0.45 | 9 AWG | 1000 | 304.8 |

| SLUL3-3107 | 3.5 | 0.45 | 3.50 mm | 1000 | 304.8 |

| SLUL3-3108 | 4.22 | 0.45 | 6 AWG | 500 | 152.4 |

| SLUL3-3109 | 5.28 | 0.45 | 4 AWG | 500 | 152.4 |

| SLUL3-3110 | 5.94 | 0.45 | 3 AWG | 500 | 152.4 |

| SLUL3-3111 | 6.68 | 0.45 | 2 AWG | 250 | 76.2 |

| SLUL3-3112 | 7.4 | 0.45 | 1 AWG | 250 | 76.2 |

| SLUL3-3113 | 8.38 | 0.45 | 0 AWG | 250 | 76.2 |

| SLUL3-3114 | 9.5 | 0.6 | 3/8 inch | 250 | 76.2 |

| SLUL3-3115 | 11.1 | 0.6 | 7/16 inch | 100 | 30.5 |

| SLUL3-3116 | 12.7 | 0.6 | 1/2 inch | 100 | 30.5 |

| SLUL3-3117 | 15.9 | 0.7 | 5/8 inch | 100 | 30.5 |

| SLUL3-3118 | 19 | 0.8 | 3/4 inch | 100 | 30.5 |

| Product Code | ID (mm) | Avg. Wall Th. | Size | Ft. | Mtr. |

|---|---|---|---|---|---|

| SLUL6-3201 | 0.5 | 0.45 | 24 AWG | 1000 | 304.8 |

| SLUL6-3202 | 1.07 | 0.45 | 18 AWG | 1000 | 304.8 |

| SLUL6-3203 | 1.6 | 0.6 | 14 AWG | 1000 | 304.8 |

| SLUL6-3204 | 2.16 | 0.6 | 12 AWG | 1000 | 304.8 |

| SLUL6-3205 | 2.69 | 0.6 | 10 AWG | 1000 | 304.8 |

| SLUL6-3206 | 3 | 0.6 | 9 AWG | 1000 | 304.8 |

| SLUL6-3207 | 3.5 | 0.6 | 3.50 mm | 1000 | 304.8 |

| SLUL6-3208 | 4.22 | 0.6 | 6 AWG | 500 | 152.4 |

| SLUL6-3209 | 5.28 | 0.6 | 4 AWG | 500 | 152.4 |

| SLUL6-3210 | 5.94 | 0.6 | 3 AWG | 500 | 152.4 |

| SLUL6-3211 | 6.68 | 0.6 | 2 AWG | 250 | 76.2 |

| SLUL6-3212 | 7.4 | 0.6 | 1 AWG | 250 | 76.2 |

| SLUL6-3213 | 8.38 | 0.6 | 0 AWG | 250 | 76.2 |

| SLUL6-3214 | 9.5 | 0.6 | 3/8 inch | 250 | 76.2 |

| SLUL6-3215 | 11.1 | 0.6 | 7/16 inch | 100 | 30.5 |

| SLUL6-3216 | 12.7 | 0.6 | 1/2 inch | 100 | 30.5 |

| SLUL6-3217 | 15.9 | 0.7 | 5/8 inch | 100 | 30.5 |

| SLUL6-3218 | 19 | 0.8 | 3/4 inch | 100 | 30.5 |

Features

Key Industries

Specification

- Widely used for Cable & Wire Harness protection.

- PVC Tubing is applied in various electronics, electrical, automobile, equipment and gadgets.

- Made from premium virgin Lead free PVC compound meeting both 90°C & 105°C applications

for both 300 V and 600 V manufactured in-house by SGI. - The Tubing has excellent Electrical and Physical properties, oil, acid and corrosion resistance as

per UL-224. - PVC Tubing is recognized and listed by UL under file no E529391 with optional Flammability

ratings ( VW-1 ) and Oil Resistance ratings. ( Class 01) for all colors except clear for size Range

0.50- 19.0 mm Internal Diameter.

- Electrical

- Telecom

- Electronics

- Defense & Aviation

- Computers

- Real Estate

- Railways

- IT/Networking

- Automation system

- Automobiles

- Electric Vehicle

- Charging Stations

| Item | Required Value UL- 224 | Observed Value |

|---|---|---|

| Material | Flexible and Non-Shrinkable PVC | Flexible and Non-Shrinkable PVC |

| Temperature Rating | 900 C & 1050 C | 900 C & 1050 C |

| Voltage Rating | 300V & 600V | 300V & 600V |

| Physical Properties | ||

| Tensile Strength before Aging | 1500 (psi minimum) | 3444 (psi minimum) |

| Elongation at break before Aging | 100% (minimum) | 115% (minimum) |

| Ageing in Circulation Oven 136.0 +- 1.0 C for 168 hrs. | ||

| Tensile Strength after Aging | 1050 (psi minimum) | 3414 (psi minimum) |

| Elongation at break after Aging | 100% (minimum) | 105% (minimum) |

| Flexibility | Shall remain flexible with no cracking or permanent deformation | No Changes |

| UL Oil resistant rating | Class 1 | Class 1 |

| Dielectric Voltage | Withstand 2500-volt for 1 minute | Withstood 5000-volt for 1 minute |

| Corrosion of Bare Copper | No corrosion | No corrosion |

| Copper Stability: Humidity of 95 ± 5 percent at 23.0 ± 2.0°C for 24 hours. Minimum Average elongation of 50% | Average elongation of 100% | |

| Deformation | 35 percent maximum acceptable decrease in wall thickness after 1hour at 131.0 ± 1.0°C | 12 percent maximum observed |

| Heat Shock | No Cracks /4 Hrs. at 180 ± 1.0°C | No Cracks |

| Cold Bend | No Cracks / 1 Hrs. at - 30 ± 1.0°C | No Cracks |

| Flammability | Meets UL224 VW-1 | Meets UL224 VW-1 |

| Volume Resistivity | 1 X 10E¹⁰ Ohm-cm | 1 X 10E¹³Ohm-cm |

| Longitudinal Change | ±5 percent after 2 hours in a circulating-air oven at 100.0 ± 1.0°C | (- 0.59) percent |

| Heat Resistance | 14 Day at 131 ± 1.0°C | No Cracking |

| Operating Temperature | -400C to 1050C | -400C to 1050C |

Brochures

View our 2023 SGI PVC Tubings brochure for an easy-to-read guide on all of the variants available.